Are you employing an outdated technique in moving parts throughout your automated finishing process?

Daisy chaining parts, when products are suspended from hooks, can cause swaying of parts, particularly as the parts move through turns, stop or start, or change elevation. That sway can also be initiated by workers who are trying to “catch the moving line” when dealing with chain-based, conveyorized, overhead finishing systems.

In power and free systems, sway can also be introduced when part carriers abruptly stop in place or switch from one chain track to another, particularly if those tracks are traveling at different speeds.

Swaying parts in the process of finishing parts adds up to lost dollars, because it forces parts to maintain greater clearances from each other as they travel through the system to avoid crashing into one another or, worst-case, falling off the line. Crashing into each other can certainly mar the finish, if not the part itself! Falling off the line is also very problematic!

There’s a better way to decrease sway in chain systems and increase part density.

Variable Frequency Drive Controlled Carriers Bring Measurable Benefits

With an IntelliFinishing system, part sway is greatly reduced via the use of variable frequency drive, or VFD, control.

With an IntelliFinishing system, part sway is greatly reduced via the use of variable frequency drive, or VFD, control.

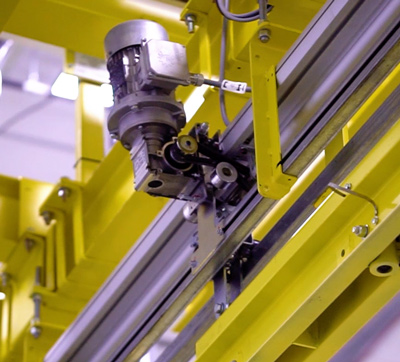

In these systems, the speed of each carrier on a section of track is independently controlled by a small motor that is VFD controlled. This VFD allows carriers to smoothly accelerate and decelerate, reducing the inertial forces that lead to excessive swaying of parts.

An IntelliFinishing system also allows parts to stop for load, unload, masking, blow off, or yes, even the finishing processes. Carriers can also speed up or slow down as may be needed or required per section of track. For example, in a non-process section of track carriers may move at speeds as high as 40 to 65 feet per minute (considerably faster than the fixed line speeds of most chain conveyors), but then slow down to under 10 fpm for a wash process or as they enter an automated finishing booth. The carriers might also index forward in an oven, as another example, in order to achieve a specific amount of time in that oven while other carriers in the oven have other time allotments for drying off or curing.

Racking Method Significantly Effects Productivity

Many users of IntelliFinishing systems choose to preload parts on removable loadbars and then hang the entire loadbar on the system from a carrier that is stopped in place. This avoids having loaders chasing after a moving chain to load the parts. After load, the carrier moves at a variable speed (basically as fast as possible) to the next step or to catch up to the carrier in front that may be waiting it’s turn in the wash or shotblast.

As a result, and especially when combined with more solid frame racking, many more parts can be hung in the same processing part window for an IntelliFinishing system.

For most systems, it takes the same amount of wash spray and time in the oven or booth to process a dense set of parts hung on a carrier compared to a lightly loaded carrier. This means that, when you can get greater part density, you can boost production without decreasing efficiency, which translates to heightened productivity. For a recent client, we were able to calculate a 20% increase in throughput per hour, simply by assuming the capacity to increase the density of parts on an IntelliFinishing System compared to traditional finishing system carrier loads.

For most systems, it takes the same amount of wash spray and time in the oven or booth to process a dense set of parts hung on a carrier compared to a lightly loaded carrier. This means that, when you can get greater part density, you can boost production without decreasing efficiency, which translates to heightened productivity. For a recent client, we were able to calculate a 20% increase in throughput per hour, simply by assuming the capacity to increase the density of parts on an IntelliFinishing System compared to traditional finishing system carrier loads.

The racking system is also a key inflection point on the journey to greater efficiency, and it’s common to question which might be right for your needs. While that will ultimately depend on the parts, in general, racking that locks a part in place is better to minimize part sway, no matter whose conveyor you use.

Of course, in powder coating, grounding through the racking is an important consideration. In this case, racking that has clean connections to the carrier or loadbar will transfer ground best and thus insure a better finish with less powder waste.

Contact IntelliFinishing Today

IntelliFinishing systems are designed with one purpose – bringing you greater efficiency in your part finishing. Leveraging VFD control to reduce part sway and boost part density is only one of the tools we have in achieving that mission.

To learn more, contact us today.

Finally, there are VFDs. Mountable in a motor control center or standalone, VFDs allow for the adjustment of motor speed over time, providing finer control while still realizing the benefits of less wear and tear on the motor.

Finally, there are VFDs. Mountable in a motor control center or standalone, VFDs allow for the adjustment of motor speed over time, providing finer control while still realizing the benefits of less wear and tear on the motor. Ultimately, using a VFD on each motor controlling a section of friction tube conveyor on an IntelliFinishing system allows users to increase part density per carrier. This means more throughput in less time. This could amount to as much as 20% more throughput! Combined with the fact that most IntelliFinishing systems are monoplane in design, there are simply far fewer chances parts will bump each other as they wander through pressure washes, shot blasts, ovens, and booths for the typical finishing system set of processes.

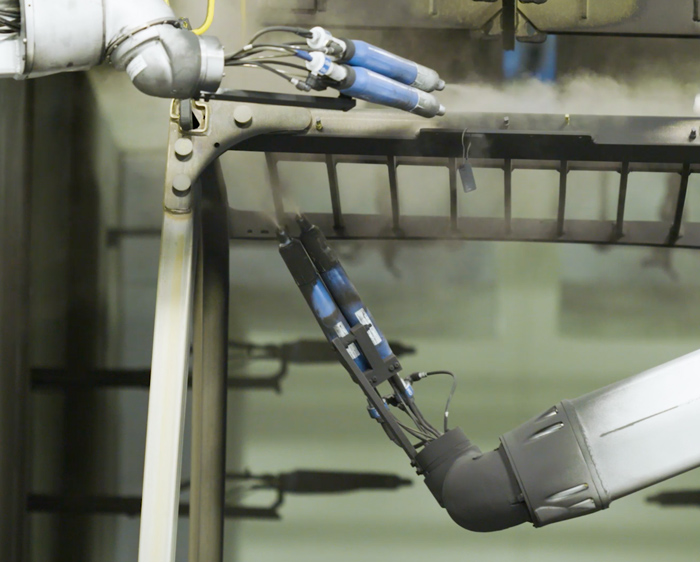

Ultimately, using a VFD on each motor controlling a section of friction tube conveyor on an IntelliFinishing system allows users to increase part density per carrier. This means more throughput in less time. This could amount to as much as 20% more throughput! Combined with the fact that most IntelliFinishing systems are monoplane in design, there are simply far fewer chances parts will bump each other as they wander through pressure washes, shot blasts, ovens, and booths for the typical finishing system set of processes. “Automating the coating process provides many benefits such as reduced labor, consistent quality, improved throughput, control over powder usage, and less waste.” Although, using robots sometimes presents challenges and for Hyster-Yale their biggest hurdle is part programming. “At this plant, we produce a wide array of products so many of the components we are powder-coating have many variants. Programming each specific robot path takes time and requires individuals with a very special skill set,” explains Wasson.

“Automating the coating process provides many benefits such as reduced labor, consistent quality, improved throughput, control over powder usage, and less waste.” Although, using robots sometimes presents challenges and for Hyster-Yale their biggest hurdle is part programming. “At this plant, we produce a wide array of products so many of the components we are powder-coating have many variants. Programming each specific robot path takes time and requires individuals with a very special skill set,” explains Wasson. Another customer, Bret Albers, Owner of Albers Finishing & Solutions, recalled their experience with using robots for their liquid painting system. He explains the biggest benefits of using robots are the consistent quality and quicker throughput, “The end result is minimal time in the booth without sacrificing finish quality.” Additionally, he explains that the IntelliFinishing system integrates extremely well with the robotics, which makes it easier to operate, control, and visually see what’s going on with the flight bars.

Another customer, Bret Albers, Owner of Albers Finishing & Solutions, recalled their experience with using robots for their liquid painting system. He explains the biggest benefits of using robots are the consistent quality and quicker throughput, “The end result is minimal time in the booth without sacrificing finish quality.” Additionally, he explains that the IntelliFinishing system integrates extremely well with the robotics, which makes it easier to operate, control, and visually see what’s going on with the flight bars. However, all customized automated finishing systems are expensive, likely costing your organization anywhere from $1 million to many millions in capital investment. While this investment will result in significant ROI and a lower lifetime cost of ownership, it’s still important to go see systems at work, especially if you don’t currently have an automated finishing system, before you even fully define your specifications.

However, all customized automated finishing systems are expensive, likely costing your organization anywhere from $1 million to many millions in capital investment. While this investment will result in significant ROI and a lower lifetime cost of ownership, it’s still important to go see systems at work, especially if you don’t currently have an automated finishing system, before you even fully define your specifications. This allows you to cater to parts that require longer cure or paint times than others. Have extra-long parts that need to be finished in a relatively small space? A shuttle system can help to avoid large radius turns. Do you feel like your processes could change over time? IntelliFinishing systems can expand or be modified, and they’re never stuck at one speed or inextricably linked to every other process.

This allows you to cater to parts that require longer cure or paint times than others. Have extra-long parts that need to be finished in a relatively small space? A shuttle system can help to avoid large radius turns. Do you feel like your processes could change over time? IntelliFinishing systems can expand or be modified, and they’re never stuck at one speed or inextricably linked to every other process. Imagine sheet metal designed to cover appliances, for example. If the IR rays beamed at the parts can reach all (or nearly all) of the surface, the IR oven can heat the product up sufficiently to cure the part in both liquid and powder applications.

Imagine sheet metal designed to cover appliances, for example. If the IR rays beamed at the parts can reach all (or nearly all) of the surface, the IR oven can heat the product up sufficiently to cure the part in both liquid and powder applications. So, with all that said, why hasn’t IntelliFinishing done many systems that use IR cure ovens? It’s certainly not because we view IR ovens as inferior – it’s because our finishing systems are best utilized by companies that have a wide variety of parts and, therefore, require different recipes per part.

So, with all that said, why hasn’t IntelliFinishing done many systems that use IR cure ovens? It’s certainly not because we view IR ovens as inferior – it’s because our finishing systems are best utilized by companies that have a wide variety of parts and, therefore, require different recipes per part. Finally, IR curing isn’t predictable in the way a convection oven can be. In order to determine exactly how long a part must cure in an IR oven, the specific parts must be tested in actual IR ovens or confirmed as viable by another organization that cures very similar parts.

Finally, IR curing isn’t predictable in the way a convection oven can be. In order to determine exactly how long a part must cure in an IR oven, the specific parts must be tested in actual IR ovens or confirmed as viable by another organization that cures very similar parts.